Consortium Partners

Lulea Tekniska Universitet (LTU)

Boliden Mineral AB (BOL)

IMA Engineering LTD OY (IMA)

Epiroc Rock Drills AB (EPI)

Retenua AB (RET)

DMT GmbH & CO KG (DMT)

Poznan Supercomputing Networking Centre (PSNC)

KGHM Polska Miedz SA (KGHM)

Geoteko Serwis Ltd. (GEO)

KGHM Cuprum Sp. z o.o.Centrum Badawczo-Rozwojowe (CUP)

DSI Underground Austria GmbH (DSI)

RHI Magnesita GmbH (RHIM)

Montanuniversität Leoben (MUL)

Joanneum Research Forschungsgesellschaft MBH (JRS)

ams OSRAM AG (AMS)

Worldsensing SL (WSENS)

Fundación TECNALIA Research & Innovation (TECN)

Universidad Politécnica de Madrid (UPM)

Minera de Orgiva SL (MDO)

Montanuniversität Leoben (MUL)

The illuMINEation project is coordinated by Montanuniversität Leoben.

Montanuniversität Leoben is an almost 200-year old global center of academic excellence in its core disciplines, oriented along the value-added life cycle from raw materials to high performance materials to recycling and secondary raw materials, accompanied by environmental and energy challenges. It offers BSc, MSc and PhD programs in all these fields. Montanuniversität Leoben and its scientific disciplines represent the future global trends of societal, industrial and scientific development, as specified in the UN’s sustainable development goals and the sustainable development strategy of the EU. As a specialised university, it offers its 4000 students outstanding infrastructure and exquisite chances on the job market. Montanuniversität Leoben aims at contributing to the responsible development of our society by providing excellent education for young people, exceptional scientific results within its core disciplines and high-quality transfer activities. Due to the applied nature, both research and education are delivered in close cooperation with the relevant industry in Austria, Europe and worldwide.

Contributions to the project will be provided by the Chair of Mining Engineering and Mineral Economics, and the Department for Industrial Liaison.

Joanneum Research Forschungsgesellschaft MBH (JRS)

Joanneum Research is leading the development of the Dependable multi-level Industrial Internet of Things platform.

JRS, headquartered in Graz, is a successful national and internationally active research institution owned by the Austrian federal states of Styria, Carinthia and Burgenland. Ideally embedded within the national and international innovation network, our researchers are excelling in three high-level fields of expertise: “Information and Production Technologies”, “Human Technologies and Medicine”, and “Society and Sustainability”.

As an INNOVATION COMPANY focusing on applied research and technology development, a key role lies in facilitating technology and knowledge transfer in Austria and Europe. It focuses on the short and medium-term technological needs of the economy. The Institute DIGITAL specialises in data-centric IoT technologies by using data from different types of sensors which fit exactly to the next industrial revolution. The involved Connected Computing research group contributes new approaches of Artificial Intelligence such as machine learning, time-aware data-analytics, and knowledge graphs combined with excellent data engineering know-how to the illuMINEation project.

Epiroc Rock Drills AB (EPI)

Epiroc is a leading global productivity partner for the mining and infrastructure industries. With ground-breaking technology, Epiroc develops and produces innovative, safe and sustainable drill rigs, rock excavation and construction equipment and tools. The company also provides world-class service and solutions for automation and interoperability. Epiroc is based in Stockholm, Sweden, had revenues of BSEK 41 in 2019 and has about 14 000 passionate employees supporting and collaborating with customers in more than 150 countries.

Epiroc’s Underground division develops, manufactures and markets a wide range of tunnelling and mining equipment, including drill rigs, loaders, mine trucks and ventilation systems, for underground applications worldwide. It focuses on innovative product design and aftermarket support systems for added customer value. The division has production in Sweden, India and China.

Epiroc is participating as partner in the illuMINEation project and contributing with the knowledge about drilling and material handling in underground applications. EPI will act as work package leader for the WP covering advanced predictive maintenance and efficient operations.

ams OSRAM AG (AMS)

AMS develops and manufactures high performance analogue semiconductors that solve its customers’ needs. AMS is a global leader in the design and manufacturing of advanced sensor solutions. Leading manufacturers around the globe rely on AMS’ sensing know-how for advanced systems design. For AMS, “Sensing is Life”, and the passion is in creating sensor solutions that make devices and technology smarter, safer, easier-to-use, and eco-friendlier. AMS’ sensor solutions are at the heart of the products and technologies that define our world today – from smartphones and mobile devices to smart homes and buildings, industrial automation, medical technology and connected vehicles.

Europe’s mining industry must completely redesign the process of traditional mining via the adoption of pioneering innovations, accompanied by extensive use of data analytics and new types of Industrial Internet of Things (IIoT) in order to reduce its import-dependency in respect to a multitude of raw materials. In the Horizon 2020 illuMINEation project, AMS will share its vast knowledge and experience on sensor component manufacturing to contribute to the digitalisation of the mining industry.

KGHM Cuprum Sp. z o.o. Centrum Badawczo-Rozwojowe (CUP)

KGHM CUPRUM, as an R&D Centre, was established in 1967 to provide a comprehensive research and design service for KGHM Polska Miedź S.A. CUP developed many solutions used in KGHM’s mines, ensuring continuous development of mining operations. The company provides R&D works for Wieliczka Salt Mine which is on the UNESCO List of World Heritage Sites. KGHM CUPRUM completed technical and economic evaluations of deposits in Europe, Asia, Africa and South America. The firm also participated in design works involving tunnels and shafts in India, Algeria, Iran and Zambia.

Core activities of the company are R&D and design works for extractive industry including:

- mining and geo-engineering, including designing, sinking and freezing mine shafts, innovative mining technologies, analysis of hazards in underground mining,

- geology, exploration works and geological projects evaluation,

- environmental protection, including industrial waste management and revitalisation of post-mining areas,

- mining heritage protection,

- copper ore processing,

- sustainable energy economy, improvement of safety and work conditions in mines, surveying.

The services we offer comprise all phases of the R&D activities from testing to design, environmental impact study, feasibility study and supervision of the implementation stage.

DMT GmbH & CO. KG (DMT)

DMT is a leading mining consultancy and engineering group with 30 offices worldwide and about 1,000 employees. DMT typically operates projects in over 25 countries per year; in the past DMT has completed thousands of projects in over 150 countries. The DMT Group provides independent services in the four main fields of Exploration, Engineering, Consulting, Geotechnics and Hydrogen Applications. It also develops products and offers solutions for industrial metrology and testing with emphasis on natural resources, safety and infrastructure. DMT operates 19 accredited testing laboratories and expert bodies, with about 100 officially recognised experts.

DMT collaborates in dedicated innovation and digitalisation activities with currently 38 large-scale international R&D projects. As European Key Innovator, DMT is an active partner in several key European innovation initiatives including the European Raw Materials Alliance (ERMA), EIT RawMaterials, Hydrogen Europe, UNECE, IAEA, EURACOAL, and the European Clean Hydrogen Alliance.

Within the H2020 illuMINEation project, DMT provides digital solutions for sensor interfaces including visualisation of condition monitoring results.

Geoteko Serwis Ltd. (GEO)

Geoteko is one of the Polish leading geotechnical companies with a group of experienced engineers that hold adequate professional certificates in the field of geotechnical engineering, environmental engineering and geology. Geoteko provides comprehensive geotechnical services that cover all aspects of geotechnical engineering i.e. investigation (including advanced field and laboratory tests), consultancy, geotechnical design and analysis. Geoteko is known for introducing new technologies and new geotechnical services to the polish market. The portfolio includes many geotechnical projects prepared for, among others, high buildings in Warsaw like Warsaw Trade Tower and Rondo 1 Tower, Żelazny Most tailings storage facility in the Lower Silesia region – the greatest disposal of its kind in Europe, the second subway line in Warsaw – currently under construction, as well as dams and bridges e.g. the Skłodowskiej-Curie Bridge in Warsaw. Geoteko has experience with working in foreign markets in eastern Europe and in Africa.

Luleå Tekniska Universitet (LTU)

Luleå University of Technology has significant experience in conducting high value research and undertaking industrial R&D projects.

Luleå University of Technology will contribute to the drone technologies of illuMINEation with the Robotics and Artificial Intelligence research subject (RAI). RAI is one of the most recognised field robotics teams in Europe with active collaborations on a global scale. It is worth to mention that RAI is also participating in the biggest robotic competition in the world from DARPA, the so-called Sub-T challenge with the Team CoSTAR. The focus of RAI is to extend the current limits of autonomy in aerial robotics by embedding to the machines advanced AI and enabling fully autonomous operations in unstructured and unknown harsh environments.

Additional to this, the researchers at the Mining and Rock Engineering division will contribute with their cutting-edge knowledge within the mining field, such as machine learning/AI and data analysis in different mining operations. The experience within rock mass characterisation, numerical modelling of blasting and measurement while drilling will also be main contributions from the Luleå University of Technology Mining researchers.

Universidad Politécnica de Madrid (UPM)

Universidad Politécnica de Madrid is the largest Spanish technological university specialised in engineering and architecture. With two recognitions as Campus of International Excellence, its outstanding research activity together with its highly qualified professional trainings, make Universidad Politécnica de Madrid a competitive university at international level. More than 2.400 researchers carry out their activity at Universidad Politécnica de Madrid, grouped in more than 200 Research Groups, 20 Research Centers or Institutes and 55 Laboratories, all of them committed to transform the knowledge generated into innovation applied to the productive sector, contributing to solve the challenges of European citizens. The intense collaboration with governmental bodies and industry guarantees that research at Universidad Politécnica de Madrid offers real solutions to real-world problems.

R&D&I activity, together with the transfer of knowledge to society, place Universidad Politécnica de Madrid among the Spanish universities with the greatest research activity, both at national and international level. Universidad Politécnica de Madrid’s highly innovation-driven focus shows by the application for around 40 patents/year and by the generation of around 20 spinoffs/year (70% survival rate), trained and mentored by the Universidad Politécnica de Madrid Center for Innovation Support.

The research group participating in illuMINEation is the Explosives and Blasting Lab, at the Department of Mining Engineering and Earth Sciences of the School of Mines and Energy. This group is well known internationally for its contributions to rock blasting research. It participates in numerous research projects and its members regularly publish in the first line international journals and more prestigious conferences of explosives and mining.

KGHM Polska Miedz SA (KGHM)

KGHM extracts and processes natural resources. The company possesses a geographically diversified portfolio of mining projects.

Polish copper deposits - one of the biggest in the world - are exploited by three underground mines: "Lubin”, "Polkowice-Sieroszowice” and"Rudna”. The extracted material is enriched in the Concentrator Plant, while the production of copper, silver, gold, lead and other metals takes place in smelters: "Głogów”, "Legnica” and "Cedynia”. On the other side of the ocean, KGHM owns six mines in the USA and Chile. Apart from copper, these mines also produce molybdenum, nickel, gold, palladium and platinum. KGHM ranks among the world's best producers of silver and copper. With its control over 22,7 million tonnes of copper ore resources worldwide. The company employs a total of 34 thousand people. It is also the only company in Europe producing rhenium and ammonium perrhenate from its own resources.

The illuMINEation project is focused on the development of a concept for continuous autonomous processing and analysis of the significant amount of data generated by the “Żelazny Most” monitoring operation. The developed technologies will improve the efficiency of data processing and analyse the current state of the Tailing Dam stability.

Minera de Orgiva SL (MDO)

Minera de Orgiva is a mining company based in Orgiva, near Granada, in Spain. The company extracts Fluorite, which is listed as a Critical Raw Material for the EU. Minera de Orgiva, as the current concessionaire, has been developing this mine since 2010 currently having a total of 145 Km of galleries.

It seems to be the only company in the whole world having all of its facilities underground (mine, crushing, milling and different concentration plants), with minimal environmental affection.

Currently having over 65 employees, Minera de Orgiva delivers its product to the major steel and cement plants along the Mediterranean area.

RHI Magnesita GmbH (RHIM)

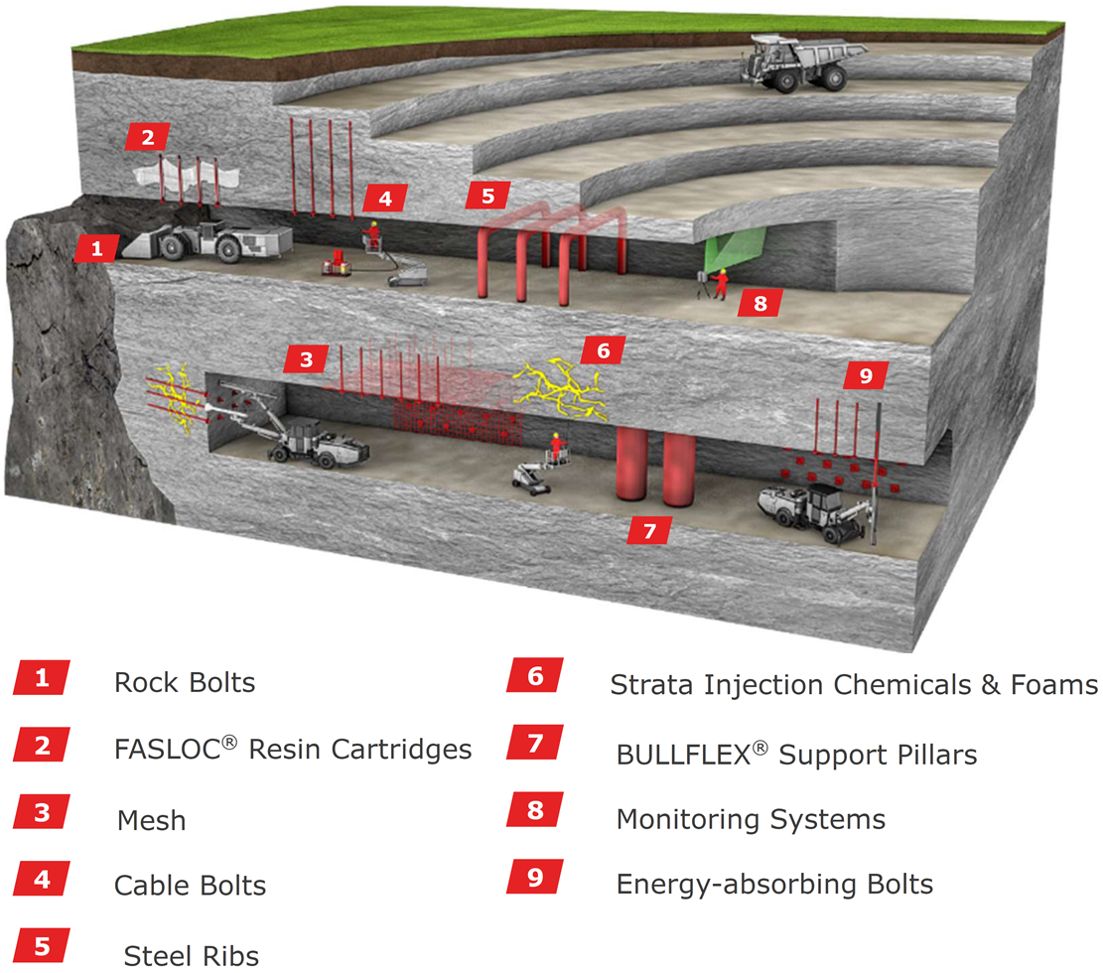

As leading global supplier of refractory products, systems and solutions with strong drive for innovation and digitalization, RHI Magnesita participates in several work packages of the illuMINEation project. The company’s plant in Breitenau, for example, helps towards the development of intelligent rock bolts, which are part of the safe zone concept for underground mining operations. Additionally, RHI Magnesita is contributing to the development of sustainable and intelligent mineral resource extraction mechanisms, specially focusing on measurement and analysis during the drilling process. Finally, the company is committed to further evolve advanced predictive maintenance and efficient operations, with special emphasis on extending machine data capturing and analysis.

The partnerships and developments resulting from the illuMINEation project underline and further boost RHI Magnesita’s drive for innovation and modernisation.

DSI Underground Austria GmbH (DSI)

DSI Underground Austria is the leading system supplier of rock reinforcement and ground support systems for the underground mining and tunneling industry. Self-drilling system solutions made in Austria such as the AT – Pipe Umbrella Support System, which are marketed under the well-known brand name ALWAG Systems, are successfully used all around the globe. DSI Underground also provides the DSI® Hollow Bar System used for bolting, forepoling, and injection works.

Industry 4.0 and the digital mine are here now, while drones and even 3D printing may drive a major step change in logistics. Where we see potential, we explore. Where we see a benefit, we invest to drive smart improvements into our customers’ operations, helping make underground operations safer, easier and more cost-effective. DSI Underground is proud to be part of the high quality and multidisciplinary illuMINEation project consortium and is looking forward to contribute to the development of ground-breaking digital bolting solutions.

Retenua AB (RET)

Retenua AB is a Swedish R&D and product development start-up company in the field of intelligent sensor systems for industrial environments. The target applications of Retenua’s technology are safe mobile machine operation around the presence of humans, machine and equipment positioning, as well as localisation and mapping for autonomous machinery. By fusion of traditional sensor techniques with recent advances in AI disciplines such as machine learning and pattern recognition, Retenua contributes to the digitalisation wave throughout the industrial sector with the goal of creating safer and more efficient work environments with smart sensors.

Retenua’s flagship product emitrace® addresses the issue of safety around heavy mobile machinery operating in industrial environments. The heavy vehicles pose a constant danger to workers on foot in the vicinity. emitrace® detects human workers equipped with high-visibility clothing from the moving vehicle and issues warning signals to allow for counteractive measures when a risk for human-machine collision is identified. The system can further be deployed for estimating the 3D location and orientation of equipment or machinery equipped with patterns of reflectors or IR LEDs and facilitate the interaction between (semi)-autonomous vehicles.

IMA Engineering LTD OY (IMA)

Ima Engineering Ltd Oy (IMA) company is focusing on developing and supplying technology, products and services for sampling and analysing elements and minerals in mining. The Ima Engineering on-line sensor technology is used in various stages of the mining process for analysing drill cores, drill cuttings, material on conveyor belt and in loader bucket. Ima Engineering’s “On-Line Mine” concept integrates analytical ore grade and geo-metallurgical information with ore location in benches, in muck-piles, in ROM pads and on conveyors with metallurgical data that is fed forward to mill and concentrator for processing optimisation and fed backwards to mine grade control and loading optimisation.

This results in reduction in waste rock dilution and in ore losses, and in solutions to sort bulk material on conveyor belt based on their grade with Ima Engineering Bulk Ore Sorting Systems (BOSS). The Ima Engineering on-line ore analysis information combined with location coordinates provides the ore value based key data for the Big Data in Mining.

Fundación TECNALIA Research & Innovation (TECN)

TECNALIA is a leading Research and Technological Development Centre in Europe whose mission is to transform technology into GDP, helping firms to be more competitive and generate wealth and employment. Its key domains are: Digital Transformation, Advanced Manufacturing, Energy Transition, Sustainable Mobility, Urban Ecosystem and Health. TECNALIA currently has a team of over 1,400 experts from 30 different nationalities. Its activity consists of identifying and developing comprehensive technological solutions together with its clients. There are more than 7,000 companies with which it has worked since its origins in 2011, 75% of which are SMEs.

TECNALIA is the first private organisation in Spain with project participation and leadership under the European Commission's HORIZON 2020 programme, in partnership with many national firms.

One of the keys to TECNALIA's success in collaborating with companies has been its commitment to maintaining a business relationship model based on trust, collaboration, and a shared technological strategy to achieve the highest value-adding proposal.

The ICT Division will be TECNALIA’s contributor to illuMINEation.

Worldsensing SL (WSENS)

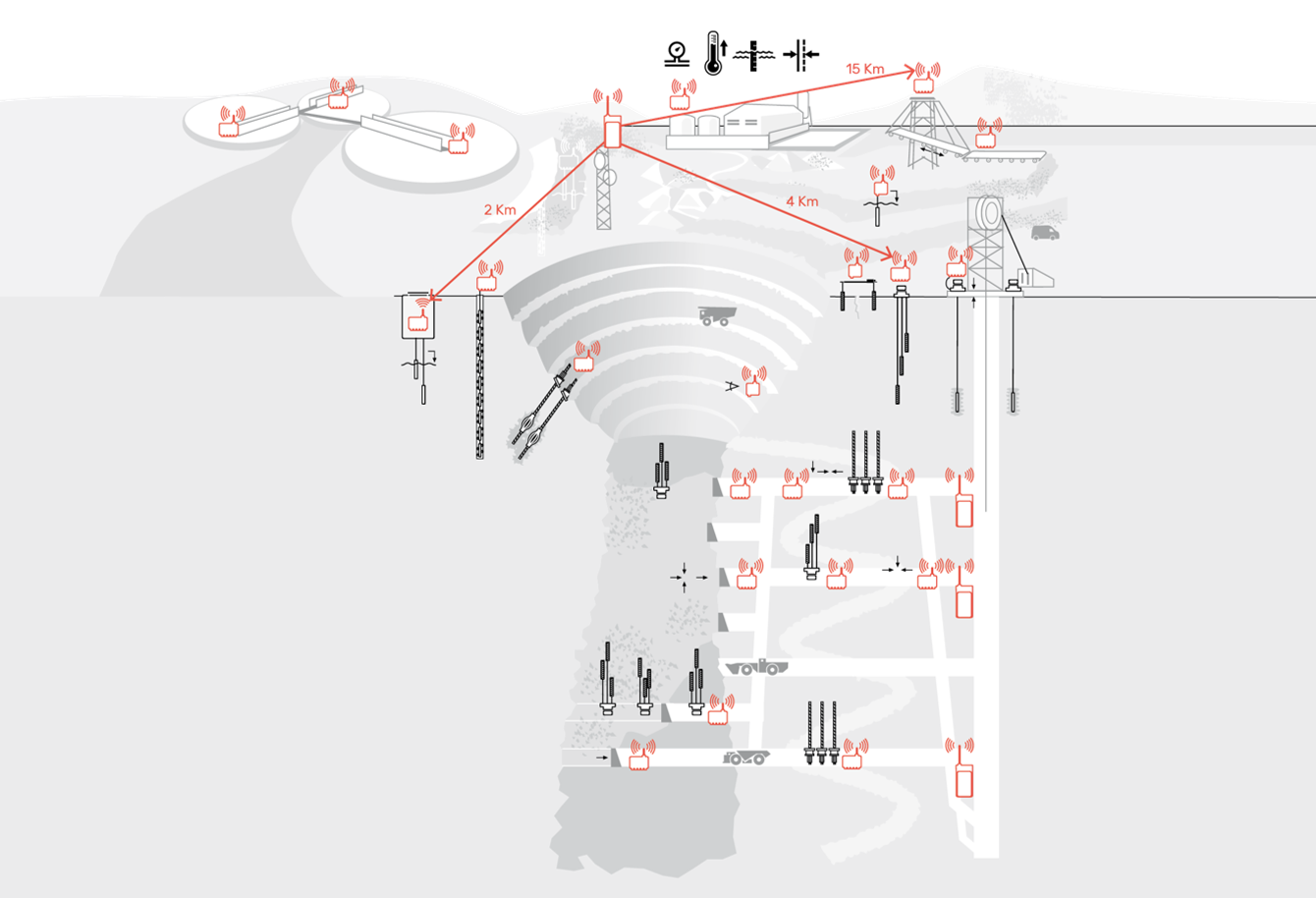

Worldsensing is a global expert of Internet-of-Things (IoT) monitoring solutions for the mining industry. In illuMINEation, WSENS will provide their IoT based Loadsensing technology and real-time software solutions.

Loadsensing connects and wirelessly monitors critical assets and infrastructure in remote locations. The wireless configuration eliminates the need for manual monitoring and expensive cabling. Having access to real-time data enables mining companies to anticipate needs, manage their workforce, diminish risks, and even prevent disasters.

Worldsensing will also be one of the partners developing the project industrial IoT platform, where monitoring applications will exploit heterogeneous sources of data to better identify dangerous situations and alarms.

The Exploitation of illuMINEation results is also led by Worldsensing, as well as the working group for Dissemination and Communication of the knowledge generated by the project.

Instytut Chemii Bioorganicznej Polskiej Akademii Nauk (Poznan Supercomputing and Networking Center; PSNC)

Poznan Supercomputing and Networking Center, affiliated to the Institute of Bioorganic Chemistry of the Polish Academy of Sciences, is an internationally known node of the European Research Area in the field of IT infrastructure of science and an important R&D center in the field of information and communication technologies (ICT). As a development centre of e-Infrastructure, PSNC designed and built the Metropolitan Network POZMAN, High Performance Computing Center and the national broadband network PIONIER, maintained and still developed by PSNC. As an important element of global research and development base, PSNC is participating in many national projects and projects under the European Union Framework Programmes, but also supporting R&D initiatives with more than a thousand partners from around the world.

In the illuMINEation project PSNC will be responsible for providing infrastructure required by the project's activities with regard to cloud computing and distributed data-management. It will also contribute to the Multi-level distributed IIoT platform design, implementation and integration as well as providing its expertise on big data, AI and analytics solutions.

Boliden Mineral AB (BOL)

Boliden is a base metals company organised into the business areas Smelters and Mines. Its core competences are within the fields of exploration, mining, mineral processing and smelting, but increasingly also sustainability and metal recycling. The company has approximately 5.800 employees. Boliden owns and operates 6 mining operations in Finland, Sweden and Ireland, mainly producing Cu, Zn, Pb, Ni, Au and Te concentrates.

Boliden participates in IlluMINEation as a Mining Industry Use Case partner, with primary focus on Intelligent Rockbolts for geotechnically safe zones in the underground mines. The company installs approximately 400.000 rock bolts per year in order to create a safe underground work environment. Sensorised “Intelligent Rockbolts” will continuously monitor and transfer information on the bolts operational status via underground communication networks, already available in the Boliden mines. Such monitoring system would allow mines to identify areas where rock support requires rehabilitation or underground areas that need to be evacuated or even abandoned. The intelligent rockbolts will be tested in two Boliden mines with different rock conditions: Kristineberg, with relatively soft rock and large deformations, and Garpenberg with more brittle rock and seismic activity.